The definition of blower:

It is a general machine that converts the mechanical energy of the prime mover into gas energy and transports gas. In fact, the blower can not produce its own wind, it only uses electricity or the energy generated by the combustion engine oil to drive the fuselage's wind blades, produce wind by changing the air pressure, and change the direction of the wind, and fix the air supply in one direction.

The type of blower

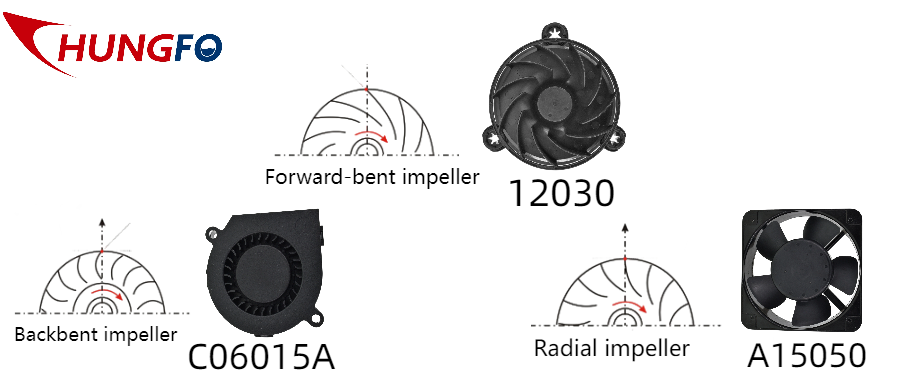

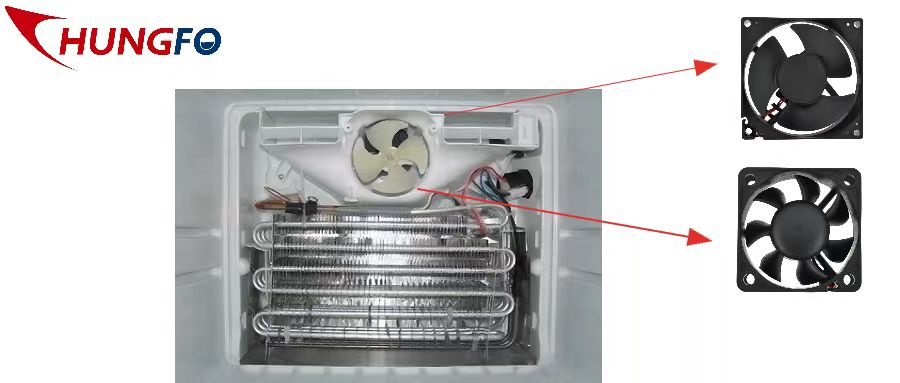

A centrifugal blower is a type of blower that accelerates and exhausts gas by centrifugal force. Its structure is simple, stable operation, suitable for conveying a large amount of gas and pressurization and other work.

Our company mainly produces and develops centrifugal blowers and DC blowers, and also produces some small blower fan. Although the application of our company's blower has been involved in many different fields, but still insist on the development of a variety of new features of the blower, such as this newly developed, specially used for household washing and drying integrated washing machine 15035 blower.

The main working principle of the general dryer is to generate power through electricity, diesel power, wind power, flammable material resources, etc., and heat the ambient air, which is transmitted to the surrounding through, and then achieve the appropriate temperature for dehumidification treatment. Under the action of the suction force of the blower, the fresh cold air outside becomes dry hot air after heat exchange with the heater directly through the air intake, and then it is discharged from the body after heat exchange with the clothes rolling in the drum, and the clothes in the drum, the water gradually evaporates and dries under the action of dry hot air.

The special feature of this model 15035 blower is that on this basis, the sealing ring is added, and the pot-sealing glue is added in the stator, which greatly enhances its water resistance, so that the blower is better protected and the service life of the dryer is guaranteed. This product is developed according to customer requirements. Our company has its own factory specializing in R & D and production, which includes R & D team, laboratory, sample group, injection molding workshop and assembly workshop. Therefore, from the production of fan blades, fan frames, fan assembly to the final packing and packing, our company handles all the steps by hand, and every step is strictly controlled. The quality of the products is very guaranteed. Welcome to consult!