In the ever-evolving landscape of industrial automation, system precision and synchronization are critical. Whether it’s coordinating robotic arms on an assembly line or maintaining consistent data flow in control systems, timing accuracy is the backbone of modern smart factories. At the heart of this timing infrastructure lies a seemingly simple component—the crystal oscillator.

The Role of Crystal Oscillators in Industrial Automation

Crystal oscillators serve as the frequency reference for nearly all electronic systems, and their importance becomes even more pronounced in industrial applications. In automated production lines, they provide the precise timing required to coordinate sequences of operations between sensors, controllers, and actuators. For example, programmable logic controllers (PLCs) and human-machine interfaces (HMIs) often rely on stable timing sources to execute commands accurately and in synchronization.

Moreover, industrial robot control systems depend on tightly regulated frequencies to ensure motion accuracy and safety. Even minor deviations in oscillator stability can lead to errors in robotic movement, causing inefficiencies or production delays. High-precision crystal oscillators, especially those with low phase noise and high frequency stability, help mitigate these risks.

What Determines Oscillator Stability?

The stability of a crystal oscillator refers to its ability to maintain a constant output frequency over time, despite changes in environmental conditions such as temperature, humidity, and mechanical stress. This is often expressed in parts per million (ppm) or parts per billion (ppb).

Key factors that affect oscillator stability include:

Temperature characteristics: Industrial environments are rarely thermally stable. Temperature-compensated crystal oscillators (TCXOs) or oven-controlled crystal oscillators (OCXOs) are commonly used where thermal fluctuations are significant.

Aging effects: Over time, quartz crystals experience slight physical changes that alter frequency. High-grade crystal units are selected for applications demanding long-term stability.

Mechanical and electrical design: Shielding from vibration and electromagnetic interference further enhances stability.

In environments with electromagnetic noise or vibration—common in factories—using a low jitter crystal oscillator can significantly improve signal integrity and reduce timing errors in digital communication or data acquisition systems.

Precision Frequency Control for Smart Factory Efficiency

Smart factories aim to optimize resource use and production speed while reducing downtime. Synchronization across devices and systems enables these goals, and precision timing is fundamental to achieving it.

For instance, in high-speed packaging or pick-and-place machines, timing delays of even microseconds can impact throughput. By integrating temperature-stable crystal oscillators, such machines can maintain consistency and reliability even under continuous operation. This allows for tighter process control and reduces the chance of errors or system interruptions.

Frequency accuracy also plays a critical role in wireless and wired industrial communication protocols such as Ethernet/IP, PROFINET, or Time-Sensitive Networking (TSN). Any drift in the reference clock can desynchronize devices, causing communication failures or data packet loss.

Choosing the Right Oscillator for Industrial Applications

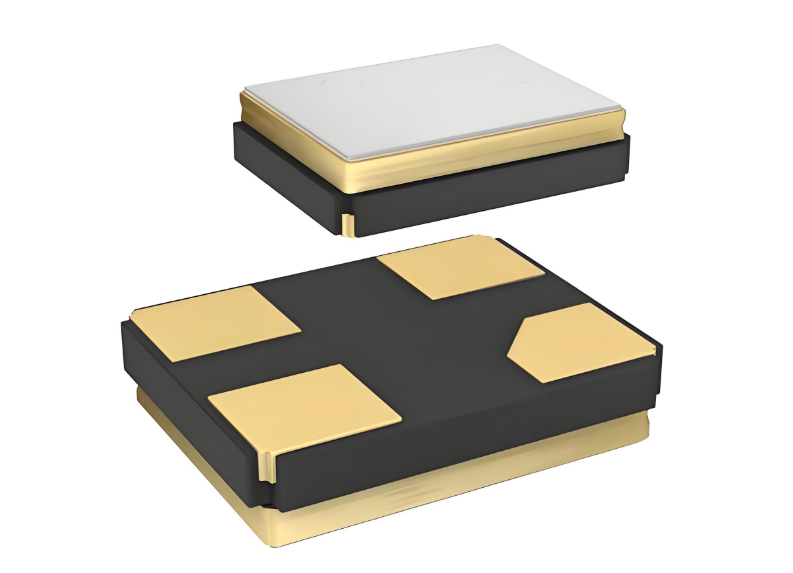

Not all crystal oscillators are equal, especially when it comes to industrial use. Design engineers must balance trade-offs between size, power consumption, cost, and performance. For high-reliability systems, SMD crystal oscillators with tight frequency tolerance and shock resistance are often preferred. Their compact design allows for integration into densely packed control boards or embedded systems.

On the other hand, TCXOs and OCXOs are more suitable when ultra-high frequency stability is essential, such as in precision metrology or high-end automation controllers. These oscillators are designed to handle extended temperature ranges and demanding mechanical conditions.

In conclusion, the stability of a crystal oscillator is a key factor in the performance and reliability of industrial automation systems. As smart factories become more advanced, with higher demands for speed, precision, and coordination, the need for robust timing solutions grows in parallel. Crystal oscillators—whether standard SMD types or specialized temperature-compensated models—enable accurate synchronization and improved equipment performance across a range of industrial applications.

By understanding the role of oscillator stability and selecting the right component for each use case, engineers can significantly enhance the operational efficiency and fault tolerance of automated systems.