When we think about the technological marvels of the modern world—from self-driving cars to sophisticated aerial drones—we often focus on the most visible components: the high-resolution cameras, powerful processors, or intricate mechanical systems. Yet, the foundational element enabling many of these innovations is an unseen and often underappreciated component: the crystal oscillator. Its precision is not just a matter of performance; it's the very basis for safety and functionality, particularly in high-stakes applications like LiDAR technology.

LiDAR's Critical Dependence on Ranging Accuracy

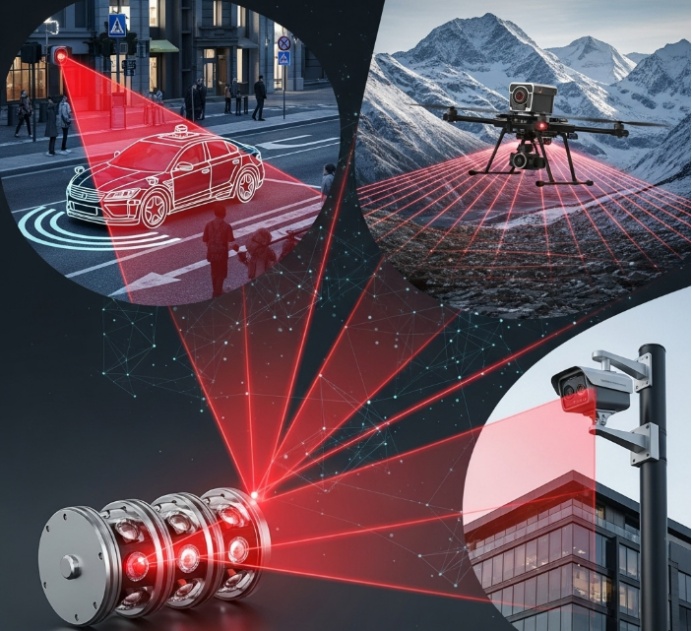

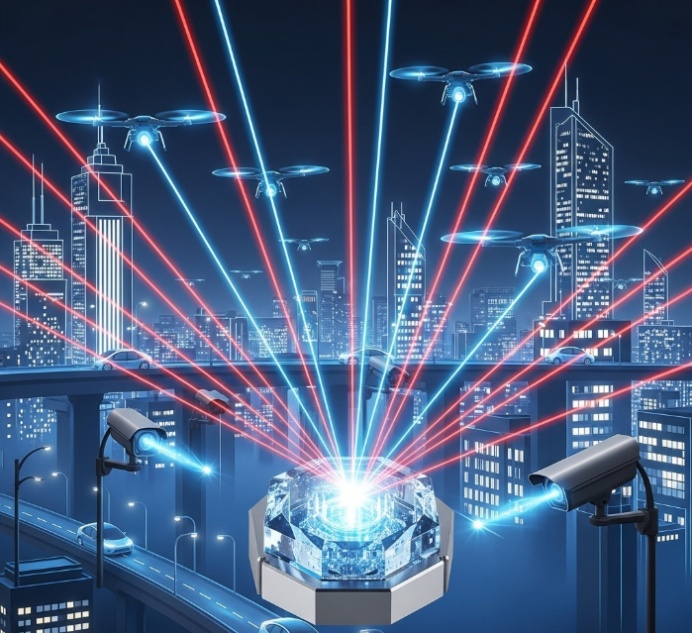

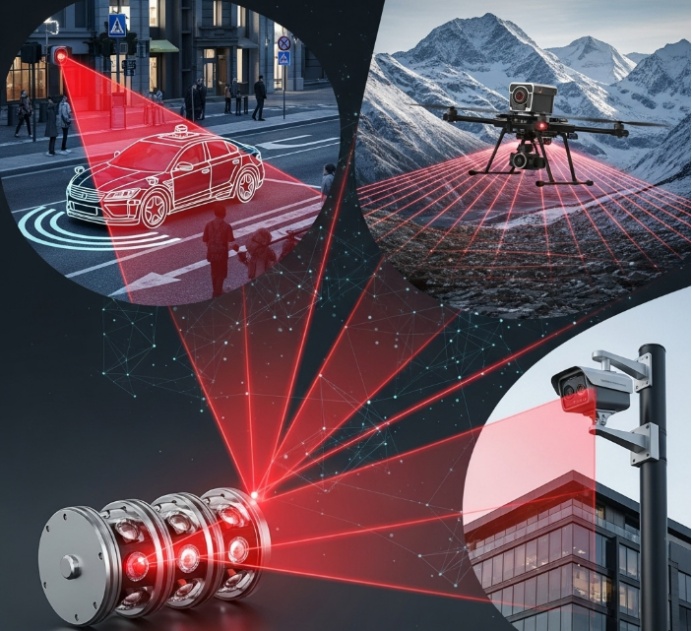

LiDAR (Light Detection and Ranging) acts as the "eyes" of autonomous systems, creating highly detailed 3D maps of the surrounding environment. This technology has become indispensable in a variety of fields, from autonomous vehicles navigating complex city streets to drone mapping for precise topographic surveys and security systems providing perimeter surveillance.

The core principle of LiDAR is deceptively simple: it sends out a laser pulse and measures the time it takes for that pulse to reflect off an object and return. This "time of flight" measurement is then used to calculate the distance to the object. For a system to reliably distinguish a pedestrian from a signpost or to map a landscape with millimeter-level detail, its ability to measure this tiny time interval must be incredibly accurate. This is where ranging accuracy becomes the most critical performance metric. A small error in the timing measurement, even just a few nanoseconds, can translate to a significant error in the calculated distance, potentially leading to catastrophic consequences in a self-driving car.

The Unsung Hero: A High-Precision Time Reference

So, what provides this crucial timing? The answer lies in a stable, high-frequency electrical signal, a clock signal, that serves as the system’s heartbeat. This clock is the master reference against which all laser pulses are timed. Without a rock-steady, consistent clock, the time-of-flight measurements would be unreliable, and the resulting 3D map would be a jumbled mess.

This is the primary role of the crystal oscillator. At its heart is a piece of quartz crystal that vibrates at an extremely precise and stable frequency when an electric voltage is applied. This natural property makes it an ideal component for generating the consistent clock signal required for LiDAR. The precision of the entire LiDAR system is, in essence, a direct reflection of the frequency stability of the oscillator.

Understanding Oscillator Precision Metrics

The performance of an oscillator is evaluated based on several key parameters that directly impact its ability to deliver accurate timing for LiDAR:

Frequency Stability: This refers to how much the output frequency of the oscillator changes over time, temperature, and other environmental factors. A high-quality oscillator maintains its frequency with minimal deviation, often measured in parts per million (ppm) or even parts per billion (ppb). In an automotive LiDAR unit, this stability must be maintained across a wide range of temperatures, from freezing winters to scorching summers.

Jitter: Jitter is the short-term, rapid variation in the timing of the clock signal's edges. Low jitter is paramount for the precise triggering of the laser pulses and the accurate measurement of their return. High jitter would introduce noise into the timing, reducing the overall ranging accuracy and blurring the point cloud data.

Phase Noise: Related to jitter, phase noise is a measure of the signal's spectral purity. Low phase noise ensures a clean, consistent signal, which is crucial for maintaining signal integrity and reducing errors in data acquisition.

For the most demanding applications like high-performance LiDAR, standard oscillators aren't enough. Designers often turn to specialized variants like TCXOs (Temperature-Compensated Crystal Oscillators) and OCXOs (Oven-Controlled Crystal Oscillators). TCXOs use a temperature-sensitive circuit to correct for frequency drift, while OCXOs go a step further by enclosing the crystal in a heated oven to maintain a constant temperature, achieving unparalleled stability.

The question of "how precise are crystal oscillators?" finds its answer in the tangible performance of technologies like LiDAR. While the laser source and photodetector are the visible stars of the show, the fundamental timing for every distance calculation is orchestrated by the quiet, consistent beat of a crystal oscillator. Its ability to provide an ultra-stable clock signal is the invisible engineering that ensures a LiDAR system's distance measurement is accurate and reliable. Without this level of precision, the sophisticated 3D maps generated by LiDAR would be little more than abstract images, and the promise of truly autonomous and safe machines would remain out of reach.